India's manufacturing sector is experiencing a significant transformation fueled by the adoption of advanced technologies. Among these, Raschel bag making machines have emerged as a key driver of innovation and efficiency. These machines, renowned for their versatility , enable the manufacture of a wide range of high-quality bags used in diverse fields. From food packaging to apparel bags and beyond, Raschel machines are revolutionizing the Indian packaging landscape.

The merits of Raschel bag making machines are extensive. They offer exceptional bag construction, ensuring durability and trustworthiness . Moreover, these machines are known for their productivity, allowing manufacturers to meet the growing demands of the market.

- Moreover, Raschel bag making machines offer a high degree of adaptability, enabling manufacturers to create bags in various dimensions and materials, catering to specific customer needs .

- Consequently , the adoption of Raschel bag making machines has led to significant improvements in India's packaging industry. It has boosted production capacity, minimized manufacturing costs, and enhanced product quality.

Continuing ahead, Raschel bag making machines are poised to play an even more crucial role in India's packaging future. With continuous innovation , these machines will further refine production processes, fulfill evolving market demands, and contribute to the growth of the Indian economy.

Innovative Advancements in Raschel Bag Manufacturing in India

India's raschel bag manufacturing is witnessing a wave of advanced technological advancements. Manufacturers are integrating new technology to improve efficiency, output, and the grade of their bags.

Automated weaving systems are modernizing the manufacturing process, minimizing manual workforce and yielding more precise results. Digital printing allow for versatile designs and patterns on the bags, catering to specific market requirements.

The use of these innovations is not only upgrading the quality of Raschel bags but also driving the development of the Indian textile industry.

Asian Manufacturers Embrace Automation with Raschel Bag Machinery

Indian manufacturers are increasingly adopting automation in their production processes, particularly in the fabrication of Raschel bags. This shift is driven by a want to enhance efficiency, minimize costs, and satisfy the growing demand for these versatile bags. Raschel bag machinery, known for its detail, allows manufacturers to create bags in a wide range of shapes, sizes, and designs.

Automation also facilitates the manufacturing of bags with intricate details, elevating their aesthetic appeal and market value.

The implementation of Raschel bag machinery has led a amount of advantages for Indian manufacturers. Initially, automation expedites the production process, reducing manual labor and as a result enhancing productivity.

Furthermore, automated machinery ensures greater consistency in bag production, leading to higher quality products. Finally, automation supports manufacturers to modify their production processes rapidly to changing market needs.

Unveiling the Raschel Bag Manufacturing Scene in India

India stands/occupies/holds a prominent position/place/role within/in/amongst the global fabric/woven textile/textile production industry, and its contribution/impact/influence to the production/manufacturing/creation of Raschel bags is significant/substantial/noteworthy.

These/They/This type of bags, known for their durability/strength/robustness and versatility/adaptability/flexibility, are manufactured/produced/created using a specialized knitting/weaving/fabric-forming technique called Raschel looms/machinery/equipment. The Indian market/industry/sector for Raschel bags is characterized/defined/marked by a diverse/varied/wide get more info range of designs/patterns/styles, catering to a broad/extensive/large customer base.

Manufacturers/Producers/Fabricators in India utilize modern/advanced/sophisticated technology and experienced/skilled/trained labor/workforce/personnel to produce/create/manufacture high-quality Raschel bags that are exported/shipped/sent worldwide.

The growth/expansion/development of the Raschel bag industry/sector/market in India is driven/stimulated/fueled by a number/range/combination of factors/elements/influences, including:

* Increasing/Growing/Rising consumer demand for durable and stylish/fashionable/trendy bags.

* A/The/An thriving textile/apparel/fashion industry in India, providing a strong/robust/solid base for Raschel bag manufacturers/producers/fabricators.

* Government/Policy/Regulatory initiatives aimed at promoting the growth of the Indian manufacturing sector.

As/With/Through the continual/ongoing/persistent innovation/development/advancement in design and production/manufacturing/creation techniques, the Raschel bag landscape/industry/sector in India is poised for further/continued/sustained growth in the years/future/coming period.

The Rise of Raschel Bag Making Machines: Transforming Indian Businesses

The common Raschel bag making equipment are rapidly changing the landscape of Indian businesses. These cutting-edge machines offer a spectrum of opportunities for Indian manufacturers, from increased production capacity to reduced operational expenses. As a result, many Indian businesses are embracing Raschel bag making machines to meet the increasing demand for durable bags in both domestic and international markets. This trend is further fueled by the government's initiative aimed at supporting industrialization in India.

Driving Efficiency and Sustainability in Raschel Bag Making in India

Raschel bag making has become vital role in the Indian textile industry. These bags, famous for their strength and adaptability, are commonly employed for diverse purposes from packing food to delivering. Raschel bag production in India undergoes substantial development due to increasing demand from both domestic and international markets.

To optimize efficiency and sustainability, manufacturers are embracing innovative technologies. Automated processes are optimizing the production process, lowering material usage and decreasing energy expenditure. Moreover, the use of sustainable materials like recycled fibers promotes ecological sustainability within the sector.

The future of Raschel bag making in India holds great potential with its focus on efficiency and sustainability.

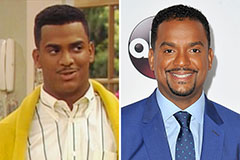

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!